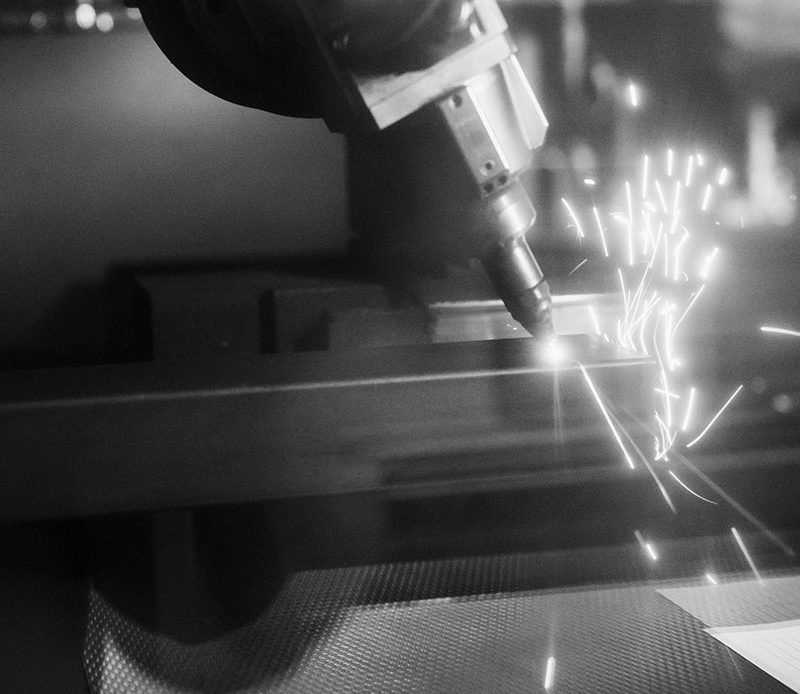

2D LASER CUTTING AND TUBE LASER CUTTING

Laser-cutting implementation follows specific protocols and is controlled by company management processes typical of the 4.0 business model. Each project is processed by our technical office, which directly uses the 3D files received from our Customers and transfers them to the CAD/CAM management system with a reduction in the development times of the order and the elimination of any errors due to the transformation of a drawing in 2D format in a three-dimensional format.

Our 2D Laser has a working range of 2000 mm x 4000 mm, and the sheet cutting follows our customer’s design. The workable materials are black sheet metal, galvanized sheet metal, stainless steel, aluminum, brass, and copper, in all thicknesses up to a maximum of 25 mm Fe.

Our Laser Tube has an automatic loader up to 8 m and an automatic unloader up to 4.50 m. We can meet every request with a range of maximum workable tubes of Ø 152 and □ 120×120 and a maximum bar weight of 25 kg/ml. The workable materials are black sheet metal, galvanized sheet metal, stainless steel, aluminum, brass, and copper, in all thicknesses up to a maximum of 8 mm Fe.

Tube Laser cutting involves drilling, slotting, notching, and inclined cutting.

Do you have any questions about our products?

Over 30 years of experience in the field of technological sheet metal processing has led us to be considered a reference company in our sector.